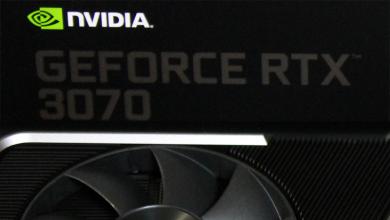

SAPPHIRE Vapor-X HD 6870 1GB GDDR5 Graphic Card

A Closer Look – Components and Design |

I would like to first point out the exposed PCB part of the video card and that the card uses the familiar blue PCB that seems to be a Sapphire trademark. Unlike the HD 6970 that we just reviewed the backside of the card is open to the air for cooling. At the top right we can see that the card does have the CrossFire connection available and the lower side tells us that this is a PCI-E card.

Using one of favorite tools by TechPowerUp the ever so informative GPU-Z we can see the details about the Barts GPU used for the Vapor-X card. The same amount of shaders, GPU clock and memory speeds are the same as the original 6870 card. What has been upgraded it the cooling of the card and the fan shroud.

The only basic design change on the Sapphire HD 6870 Vapor-X is the shroud that cover the cooler and entire card. Because of the usage of the vapor-x technology cooling system a slight change was needed and to help create a distinctive look for the new Vapor-X card.

Eyefinity technology is ideal for multimedia applications The output side of the card give us plenty of ways to use the card which include ATI Avivo HD (DVD/HD-DVD/Blu-ray Playback), AMD HD3D Technology, Dual-Link DVI, Single-Link DVI-D, HDMI 1.4a, Mini-DisplayPort and DisplayPort 1.2. With all those points of connection you are able to have to six monitors from this single card, but you will have to use some DisplayPort extenders.

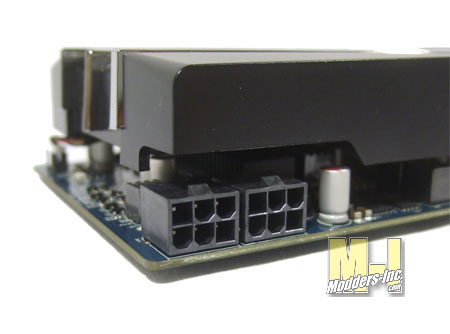

Two 75Watt 6-pin PCI Express power connector are required to supply enough power to the card. From this angle we can also see that the card uses Solid Capacitors. What we see is a Black Diamond Choke & Full Solid Cap Design. Choke is an important component of the graphics card and Sapphire’s patent pending choke is 10% cooler and offers 25% more power efficiency than a normal choke. This makes the graphics card more reliable and saves energy. Improved reliability and better overclocking are possible by using only high-polymer, aluminum capacitors which posses far superior characteristics than regular aluminum capacitor for a longer product life. When operational temperatures drop by 20°C, the product life span is extended by a factor of ten, when the operational temperature increases by 20°C, the product life span only decreases by 10%.

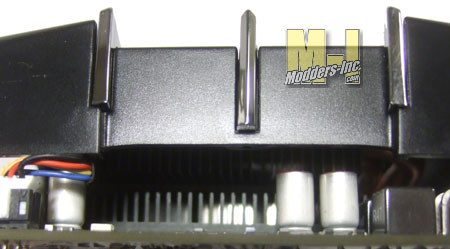

Part of the redesign of the cooling system is the addition of the air ducts for the cover on the card. Allowing air to flow freely where it is needed.

The Vapor Chamber Technology is based on the same principles as heatpipe technology. A liquid coolant is vaporized at a hot surface, the resulting vapor is condensed at a cold surface then the liquid is returned to the hot surface. The recirculation process is controlled by a wick system.

Looking deep into the heart of the card we can see that the cooling system the SAPPHIRE Vapor-X flattens the whole system into a slim chamber – which in the graphics application is mounted in contact with the surface of the graphics chip.

The coolant used is water – but because the chamber is evacuated to a very low pressure, the vaporization process occurs at a much lower temperature than normal boiling point. The complex wick arrangement inside the module controls the flow of water and water vapor so that the system can be used in any orientation.

So how does Vapor-X work?

So in the SAPPHIRE graphics application, the heat source is the graphics chip. The Vapor-X module is mounted in contact with the surface of the chip. The Vapor-X module is much more efficient than a copper heat sink at carrying away the heat because the whole area effectively transfers heat at the same rate. The cool surface is maintained by a heat sink and air flow across it – the exact design of which depends on the power of the graphics chip and associated memory components.

|

Heat source heats Vaporization Wicks.

Heat source heats Vaporization Wicks.