Plexiglass Basics: What you need to know

There are several tools for cutting plexiglass. You can use a hacksaw, jigsaw, dremel with a cutting bit or blade, plexi tool or razor knife.

Plexi cutting tools

Cutting blade � Note the 32 teeth per inch

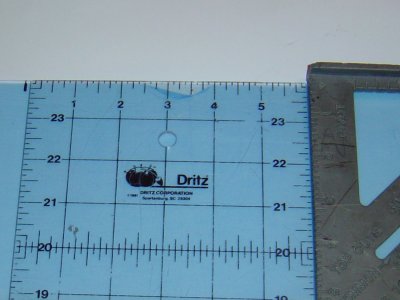

They all have places where they work best for certain mods. With all cutting some extra time should be left for clean up, straightening, and polishing if desired. Straight cuts in thin material can be done with a knife or a sharp blade. Start with a straight edge or a square. After lining up your marks, press firmly to hold the alignment.

Note the extra left over.

Drag the blade down the straight edge lightly the first time to get a good straight cut and then several times to cut into the plexiglass.

Side view cut about half way through

Next turn the piece over, hold the larger piece down with a lot of pressure, and start to lift the other piece till it breaks on the cut you just made.

Breaking the sheet at the score � notice the bowing before it breaks

The dremel is a great tool for rounded corners, inside cuts and large odd shaped holes. There are two bits that work well for plastics, a milling style bit and saw style.

Rotary Milling bit

Rip blade

Cutting holes with a milling bit you will need a starter hole about twice the size of the bit. Start with some scrap to check your speed of the tool, rotation of the bit as one direction with not cut as clean and how fast you can cut without slowing the bit and melting the plexiglass. Heavier material takes more time to cut. Once these things are known go to cutting your pieces for your mod.

Milling Plexiglass for a inside corner

Finished cut ready for finishing.

With heavier plastics a saw of some kind is good for straight cuts. Go slow as the plastics will get hot enough to melt instead of cut.

after cutting with a saw.