Noctua NH-D14 CPU Cooler

With a monster, comes monster fans |

|

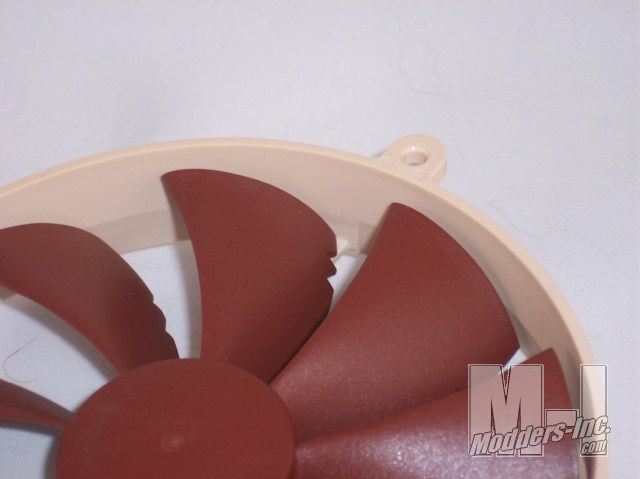

I want to spend some time on the fans in this unit, simply because their effectiveness cannot be understated. Earlier in the article I spoke to you about some technologies that were in this. Things like: Self Stabilizing Oil pressure Bearings, Vortex control notches, and the advent of their SCD (Smooth Commutation Drive) system. While those terms may come across as marketing hype or over complicated words to describe technology, I must say that when you have used as many different types of fans as I have, you notice things. And when you notice things immediately like airflow *and* silence… you take serious notice. All of these items used in conjunction with one another have made me a (pardon the pun) fan of the red clay colored air movers. I had to learn more about how they did this.

I had to remove the fans to install the heatsink on my motherboard. In doing so, I started them up independent of one another, as well as with other fans of equivalent size from other manufacturers, in order to make sure I was hearing and feeling these things correctly. So, lets talk about what makes these fans so great.

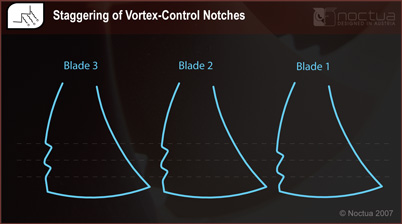

Vortex Control notches

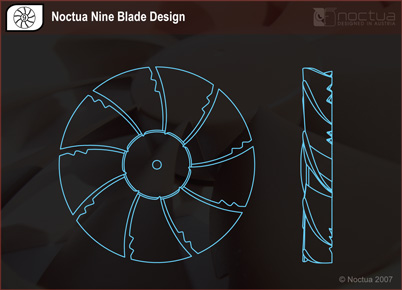

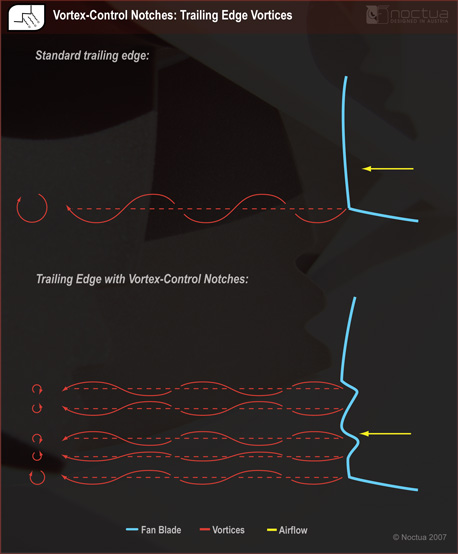

The Vortex Control Notches (VCN’s) are a way for the fan to help eliminate noise by helping mix the air on the suction and pressure sides of the fan blade.

Per their website: “As a matter of principle, increasing the number of blades involves the risk of increasing the aerodynamic noise in general and noises caused by rotor-stator interaction in particular. Basically, an increase in static pressure usually brings about higher noise emissions. In the case of the NF-P12, this problem is dealt with by adding Vortex-Control Notches to the blades’ trailing edges. Due to the two notches at the trailing edge, the flows along the suction and pressure side mix more smoothly. This allows for less turbulence and velocity loss, which leads to a significant reduction in noise emission as well as increased efficiency. In order to achieve the smoothest possible transition and maximum noise reduction, the Vortex-Control Notches are rounded in shape.” “In addition to optimizing the joining of the flows at the trailing edge, the Vortex-Control Notches fulfill the task of psycho-acoustic optimization: Due to the Vortex-Control Notches, trailing edge vortices are split up into several smaller vortices. Thus the noise is spread over a wider range of frequencies and therefore perceived as much less annoying.” “The Vortex-Control Notches’ effect of psycho-acoustic optimization is further enhanced by the staggering of the notches. The Vortex-Control Notches are staggered from blade to blade so that each blade creates a different vortex pattern. As a result, the fan’s noise emission is better spread over the frequency spectrum and thereby makes it yet more pleasant to the human ear.”

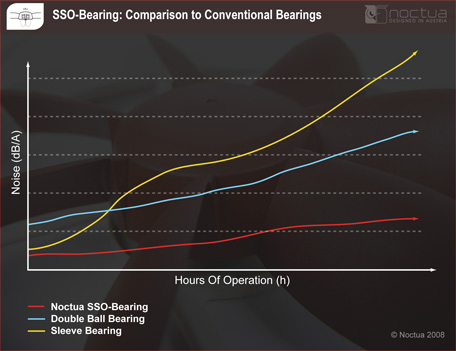

So, they optimize the flow, and the sound they cannot get rid of off of the blades, they “disguise” by spreading it across the sound spectrum… effectively diffusing the sound across the audible spectrum. So, instead of an unoptimized “single channel” hiss or whistle that is in one spectrum, they found a way to make the sound as disguised as possible. In-genius! Self Stabilizing Oilpressure Bearings Not wanting to take apart my fans and gut these beauties, I dove into the Noctua website and found my answers on the SSO technology. Effectively, the design is to optimizes performance and noise over the long haul. Typical sleeve or ball bearing style fans may start off quite, but tend to deteriorate more over time, leading to increased noise of the fan unit. Again, these fans have a warranty for 6 years… so, you had better be engineering the fans to last!

To quote their site: “The sleeve and ball bearings currently predominating the fan market exhibit major drawbacks: While conventional sleeve bearings initially have very low noise emissions, they mostly possess unsatisfying long-term stability, which leads to a short overall lifespan and increasing noise after longer operating times. High grade ball bearings, on the other hand, while providing satisfying long-term stability operate at slightly higher noise levels from the beginning. The SSO bearing not only surpasses the quietness of conventional sleeve bearings but also the long-term stability of current top-of-the-line ball bearings.” SCD (Smooth Commutation Drive) They even found a way to optimize the stator switching in the fan motor. “Next to aerodynamic noise and bearing related noises, the so called “commutation noise” or “switching noise” can play a major role in the noise emission of axial fans with brush-less DC motors. At each transition from one stator coil to another, the rotor receives a sudden torque pulse when the next coil switches on. Each of these torque pulses causes a minute deformation of the whole fan structure. Depending on rpm, torque and the material of the fan, this can result in noticeable noises. Noctua’s Smooth Commutation Drive system provides more continuous switching in order to achieve a smoother transition between the stator coils and thereby significantly contributes to the fan’s overall quietness. The second generation of this technology (SCD2) further improves running smoothness and reduces minute noises in close proximity to the motor.”

So, they tackled fan blade noise by using staggered VCN’s on the trailing edges of the fan blades to remove some turbulence as well as spread the sound frequency, optimized the interface between the fan housing and the motor/stator, *and* they optimized the stator switching to smooth the fan drive…. And you thought they were only fans! |