Noctua Industrial PPC Fans Revisited: 24V Models and Chromax Colour Accessories

Noctua IndustrialPPC 24V and Chromax Accessories Overview

The Noctua IndustrialPPC NF-F12 is physically a color-swap of the original NF-F12 but they are internally different. The body of the Industrial PPC fans themselves are made from Fibre-glass reinforced Polyamide (PA) so it is tougher than the Fibre-glass reinforced Polybutylene terephthalate (PBT) bodies of the regular segment and Redux Noctua fans. The motor has also been bumped from single-phase (4 poles, 4 slots) design to a three-phase (4 poles, 6 slots) resulting in higher frequency switching and evened out torque variations. The Industrial PPC fan driver ICs have also been tweaked to be much more efficient by around 10% compared to the retail Noctua fans, requiring less power to run at the same RPM output. The newer 24V Industrial PPC models use a dedicated wide input range version of this three-phase motor driver IC to support industrial applications of 24V while running at a more silent, lower RPM when plugged in to a 12V power source.

The NF-F12 has seven blades but they are very wide and have sharp angled corners compared to the more rounded corners of the NF-A14. The blade leading and trailing edges barely curve and look almost as if they are straight edges at first glance. Unlike the NF-A14, the blades do not have suction-side flow-acceleration channels but the Advanced Acoustic Optimization frame design is present. Noctua dubs the NF-F12 as a “focused flow” fan and it makes use of eleven stator guide vanes with varying angles (from 31 to 37 degrees). These vanes have vortex-control notches similar to some Noctua fan impeller blades for better acoustic profile. The focused flow design also makes them efficient as radiator fans hence Noctua bundles the NF-F12 in their 120mm heatsinks.

The NF-A14 design utilizes seven wide blades as well with curved corners unlike their older Noctua NF-P14 design. There are only four struts compared to the focus flow NF-F12 and these struts are straight toward the centre but curve once it approaches the edges.

The AAO frame comprising of the stepped inlet design, inner surface microstructures and integrated vibration pads alleviate noise problems that may arise or at least keep it as low as possible relative to the airflow produced. The tips of the blades have flow acceleration channels in the intake side for speeding up airflow on the outer edges which reduces vortex noise related to flow separation.

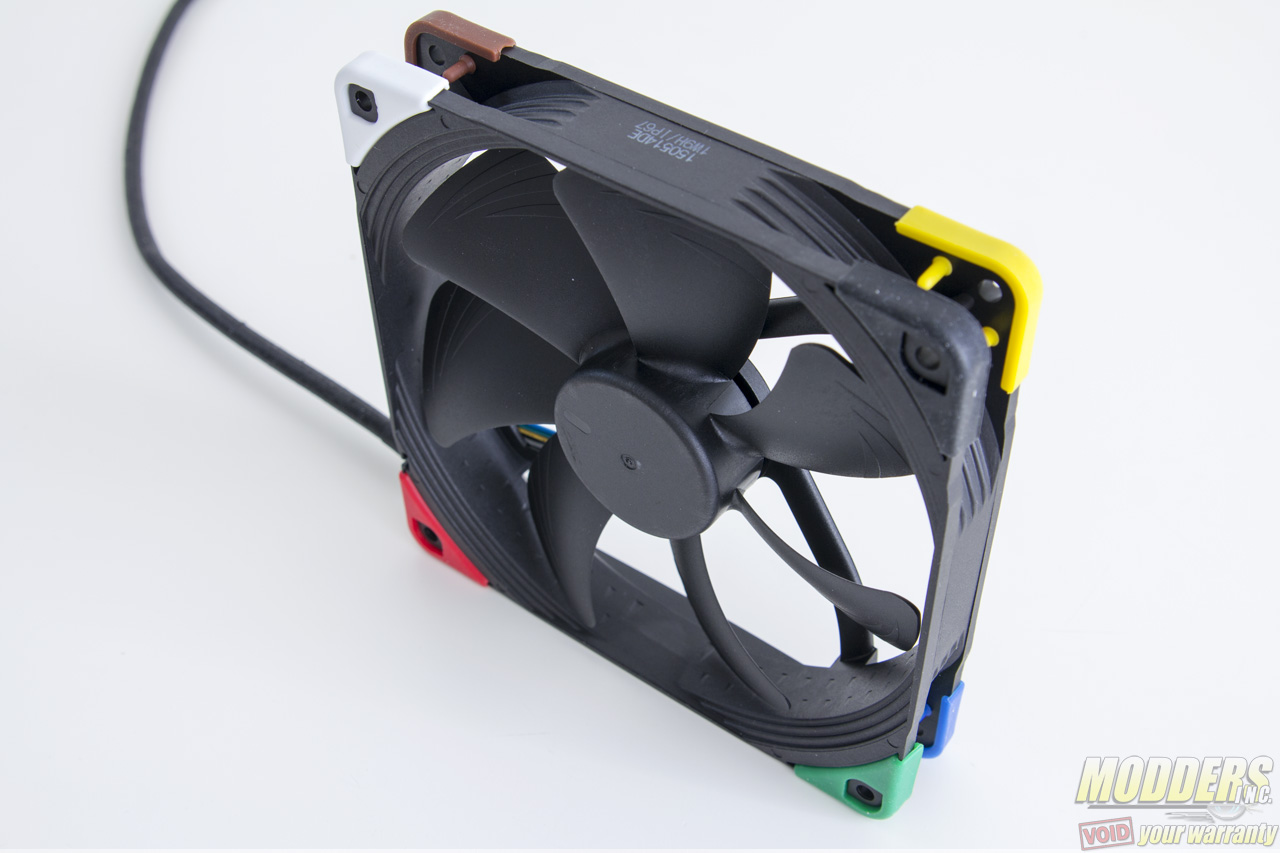

The NA-SAVP1 corners are compatible with most Noctua fans that follow a similar form factor. The NF-A14 with a round frame however cannot use it because the pads are different shaped. Installation does not take much effort, requiring users to only pull one out and replace a different color of their liking. The white corners look particularly good with the Industrial PPC’s black frames, but if one is crazy enough, you can even mix and match all colors on one fan.

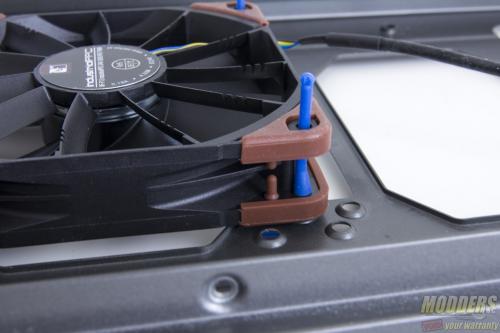

Installing the NA-AV2 is fairly straightforward as well, requiring users to install the shorter side on the case while the longer side goes through the fan mounting holes. Users just simply need to tug until it is passed through to secure it in place.

Depending on your case, these NA-AV2 might not be usable if the mounting plate is too thick or if there is no clearance on the other side such as this Switch 810 case that has the HDD cage blocking the other side of the fan intake area. In this case, a regular long screw would be more applicable, relying on the NA-SAVP1 corner pads to dampen the vibrations of the high-RPM Industrial PPC.