Acrylic: A Case Modder’s Material

Panel, panel on the wall who is the fairest acrylic of them all?

Acrylic is possibly the most versatile material used in case modding. Not only can it be used to show off your components as a window in your case, it can be used to actually be your entire case. From sheets, to spheres to rods and blocks, acrylic comes in a multitude of different sizes, shapes and even colors to suite your build. A simple Google search for “acrylic” might turn up several thousand results and for a beginner in case modding this can be overbearing. That’s why here at Modders-Inc we are here to shed some light on the different types of acrylic you might encounter and how you might use them.

Acrylic, what is it?

Acrylic or Poly(methylmethacrylate) PMMA, is transparent thermoplastic that is often used in place of glass. It is often cheaper than glass and has a much higher impact strength over glass. You might also know it by a few names such as, plexi, plexiglass, lucite and perspex.

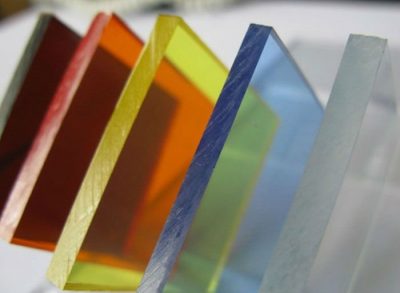

Just clear?

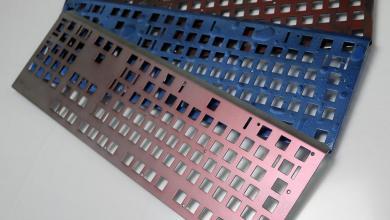

Acrylic actually comes in a large selection of translucent, opaque and frosted colors to better suit your build. Now with this said not all colors of acrylic are created equally. For example translucent red, is considerably weaker than an opaque black. The reason for this is colors added to the mix, for translucent colors, the bonds inside of the material are much weaker, which allows light to pass through. With opaque colors the bonds are much tighter and almost no light will penetrate through the material. The result is a much stronger material which is better for construction style applications.

Cast or Extruded?

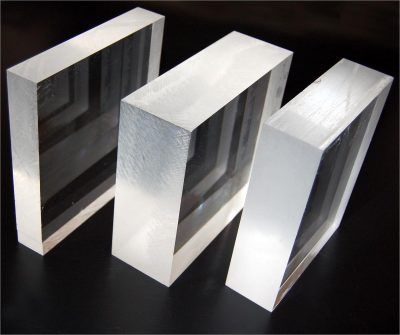

The two most common types of acrylic you will see are what is known as cast and extruded.

Cast acrylic is acrylic that is formed through by pouring liquid plastic, into a mold and treating it through a gradual heating process, until it cures to its final solid form. This creates a much stronger material and allows for machining, without clogging up tools.

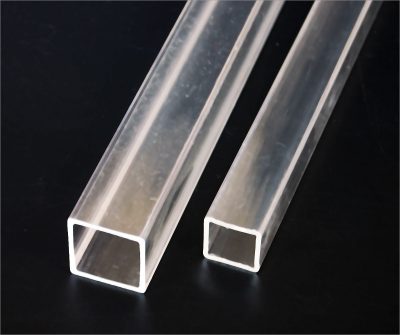

Extruded acrylic is acrylic that goes through a high pressure system, that heats the plastic pellets to a molten state, then presses the molten plastic through a die which determines the shape and thickness. Then is cooled and trimmed to its desired lengths. Because of this most acrylic you see in prefabbed shapes is extruded which saves on milling time.

For modding, it’s best to stick with cast acrylic as it takes tooling better, comes in more colors, is structurally stronger and takes polishing/painting better than its extruded counter part.

Will it bend?

Here we have Lee Harrington’s of PCjunkieMods, “Simplicity” rig showcasing bent acrylic tubing, as well as the EK Vulture case which features a bent acrylic window.

When heated it can become flexible and be bent into a variety of different shapes. In modding we see this commonly practice with hardline bending, and for making power supply shrouds. It should be noted that the most common material used for hardline bending is not actually acrylic but a familiar material known as PETG (Polyethylene terephthalate.) This material looks like acrylic but has a much lower melting temperature and has an extremely high impact rating.

Where can I buy acrylic?

Delvie’s Plastics: http://www.delviesplastics.com/

TAP Plastics: http://www.tapplastics.com/

Now this is only a few places on the web where you can get acrylic from, so feel free to search around for yourself.

McMaster: http://www.mcmaster.com/

*Images used in this article are property of their original owners: Petersen Plastics, Delviesplastics, TapPlastics, eplastics.com, http://www.facebook.com/pcjunkiemods